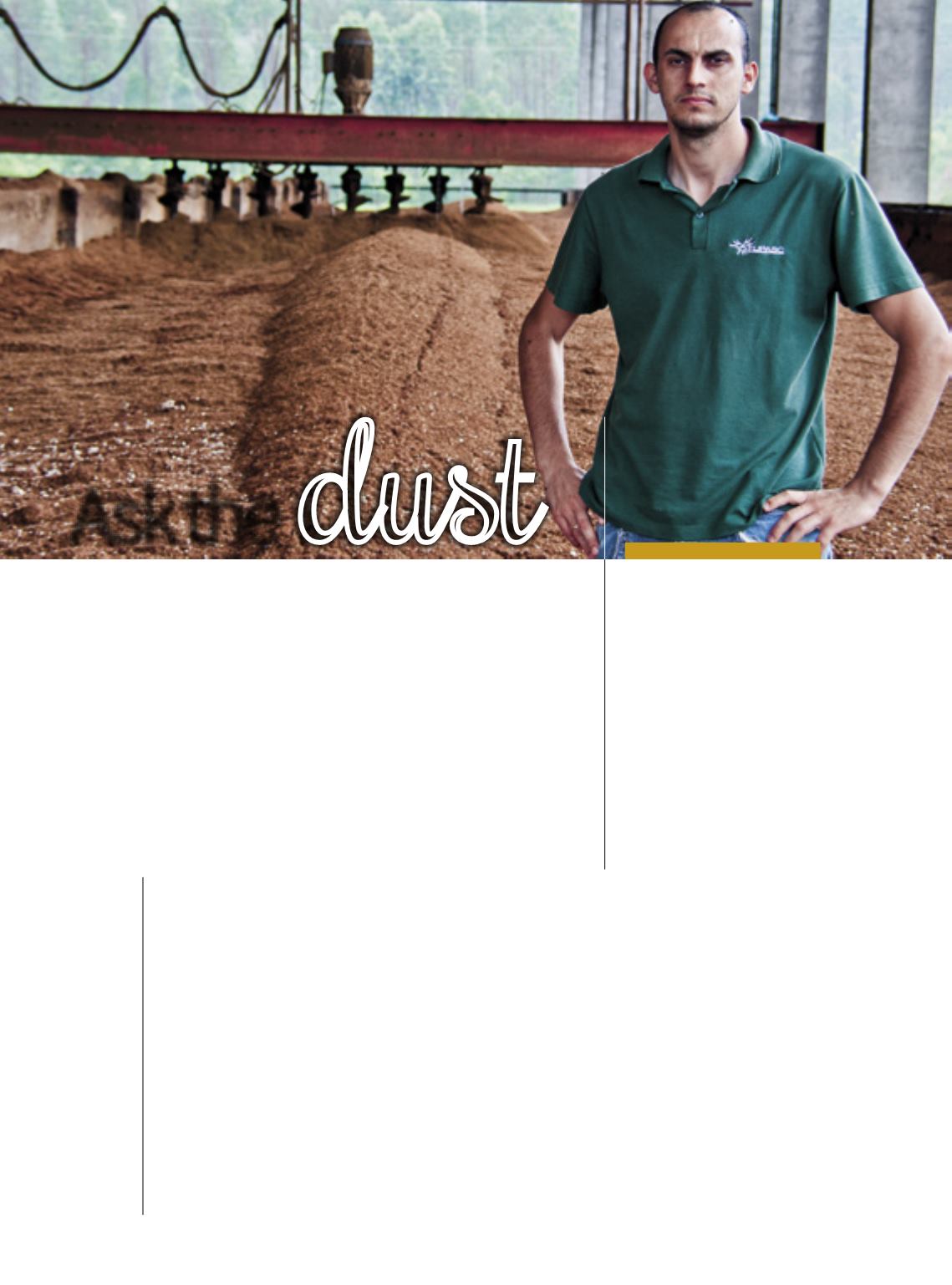

A

n unprecedented technology in the world is now reaching its third

growing season in Brazil, with promising results for the entire tobac-

co supply chain. At the Santa Cruz do Sul Environment Protection

Foundation (Fupasc), what used to be industrial waste for the tobac-

co companies, is now transformed and reused. Through a compost-

ing process tobacco dust is now given a useful destination and returns to the fields

in the form of organic fertilizer. The treatment, consisting in fermenting the waste

in its solid state, is the result of more than 10 years of research works, in a joint ef-

fort by the sector.

According to Sebastão Dionis Bohrer, environmental and work safety engineer,

coordinator of the environment department at Fupasc, in the past, the companies

were authorized to incorporate the tobacco dust, without any treatment, into soil.

When the changes in Brazilian legislation became more restrictive, the manage-

ment and the destination of this waste required investment in research. At that

Tobaccodust

generatedby

theindustryis

transformed

intoacomposting

processand

returnstothe

fieldasorganic

fertilizer

moment, Universal Leaf Tabacos took the initiative to invest in technological research, which resulted into the con-

sortiumof microorganisms to speed up the composting process. The technology, tested and approved, was denom-

inated Bioleaf and was registered in the Ibama. In 2014, its operation was undertaken by the Fupasc, making it pos-

sible for other companies to join the initiative, while the foundation began to be remunerated for services rendered.

Fupasc’s processing structure, established in the interior of Santa Cruz do Sul (RS), consists of upwards of 7 thou-

sand square meters under roof, exclusively destined for the tobacco dust treatment operation. “Per growing sea-

son, the amount of dust amounts to upwards of 10 million kilograms. In three years, the system has already treated

30 thousand tons”, explains Bohrer. For 2017, the expectation is for a 25-percent increase in this volume, close to 13

thousand tons. With a register in the Ministry of Agriculture, Livestock and Food Supply (Mapa), the entire amount

of product is monitored by lot, where 33 parameters are analyzed, which attest to the fertilizers that are produced.

With regard to the logistics of the process, the foundation receives the raw dust from the associated companies,

adds the microorganisms that promote the composting process. After the inoculation, the product is submitted to

a 90 to 120 day maturation phase, until it is completely stabilized, ready to be taken back to the companies. “At the

end of the process, the result is an organic fertilizer known as FertiLeaf, whose cycle is a reversal to the productive

cycle. That is to say, the tobacco company generates the waste, Fupasc treats it and returns it as a clean product,

ready to be used as fertilizer. It is a closed management cycle”, he argues.

n

dust

Ask the

Inor Ag. Assmann

72