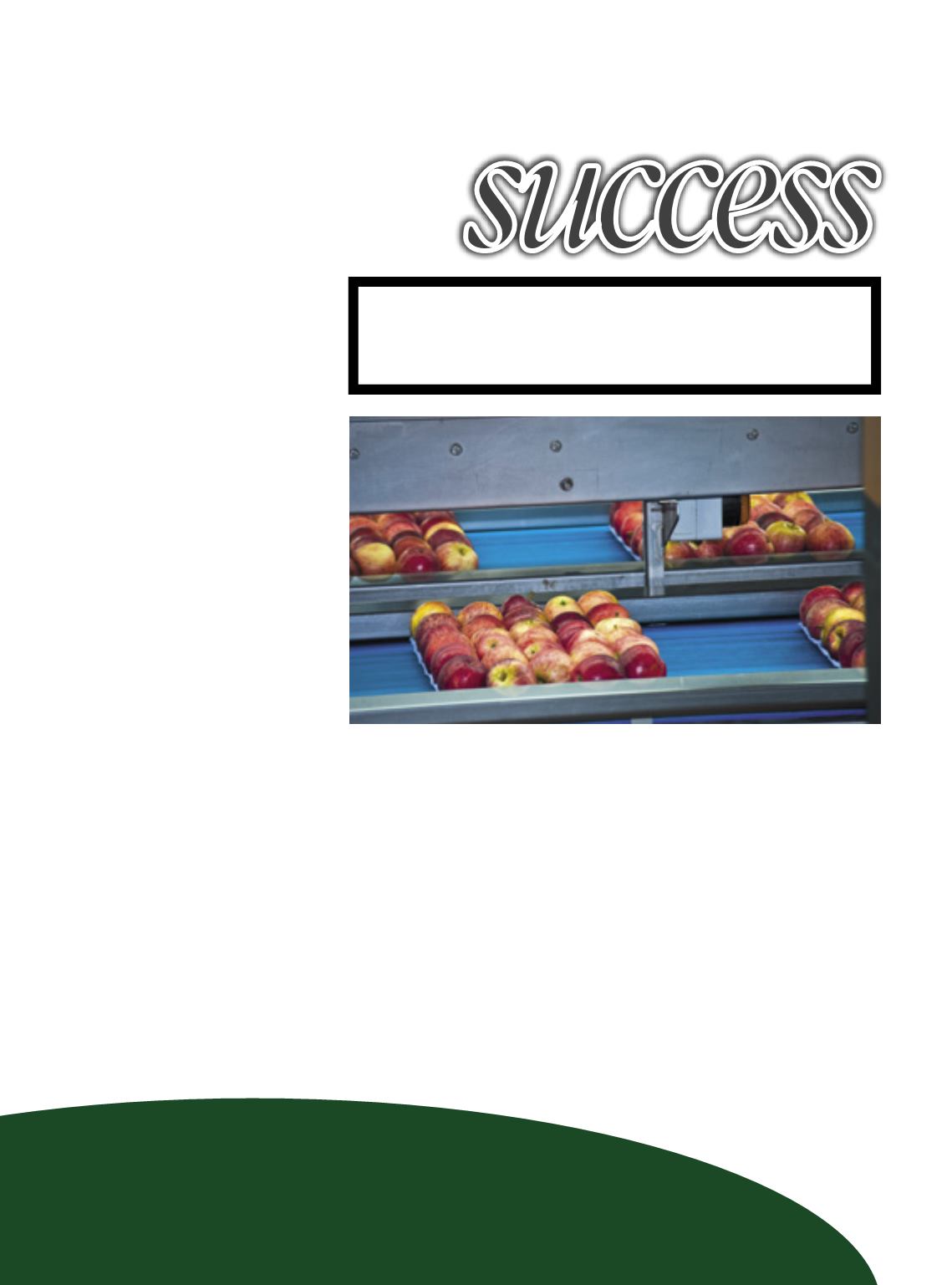

Modern processing andwarehousing

structuresestablishedinthecompaniesensure

standardizedproductionsuppliesforlongerperiods

T

hemost of the apple volume

commercialized in Brazil

goes through medium-sized

and large companies estab-

lished in the producing re-

gions, and they equally account for a huge

portion of the rawmaterial. With big invest-

ments, the entrepreneurs offer state-of-the-

art structure, with the most advanced tech-

nologies available at global level, with the

aim to ensure production quality and stan-

dardization of the crop harvested at the

beginning of the year, besides the main-

tenance of the good conditions for an unde-

termined period of time.

The value invested in packing hous-

es and cold storage facilities, according to

the Brazilian Association of Apple Producers

(ABPM), corresponds to about R$ 2.5 billion,

and reaches more than R$ 4 billion is the re-

sources invested in orchards, with insurance

against hailstorms included. At least 300 re-

ceiving, grading and production processing

structures , are operating in the first half of

the year in all major apple producing regions

in South Brazil, while the medium-sized and

large companies, with greater storage capac-

ity,maintains theoffer throughout theyear.

Besidesthetraditionalrefrigeratingtech-

niques, controlled atmosphere with low ox-

ygen and the use of growth regulators, the

sector shows evolution in warehousing un-

der dynamic atmosphere. According to Luiz

Carlos Argenta, researcher with the San-

ta Catarina State Rural Extension and Agri-

cultural Research Company (Epagri), this is

the way to reduce oxygen concentrations to

lower levels than usual and modified in ac-

Sector uses sophisticated

grading and conservation technologies

cordancewith the physiology of the fruit.

The specialist in post-harvest also

comments that a quality database kept

by the sector allows for constant com-

parisons and warning signs in the ware-

housing facility. “There is permanent con-

cern about monitoring this aspect, so

as to commercialize the fruit at the ideal

time, without losing their best consump-

tion conditions”, Argenta observes. The

segments warehousing capacity reach-

es 923,341 tons, say ABPM officials, very

close to the volume produced at every

crop year. A small portion (approximately

15%) is destined for the production of juic-

es, most of which are sold in bulk.

Complex production, industrialization

and commercialization system is what char-

acterized the Brazilian apple supply chain.

It generates wealth for the communities

and states where it is produced through-

out theCountry, besides showing great con-

cern about environmental and social proj-

ects in the locations where it operates. The

high level of the crop is ensured by several

global certifications. The supply chain raked

in revenue of about R$ 2.2 billion in the past

cropyears, while the total amount ofmoney

involved with the area amounts to R$ 6 bil-

lion. It also offers job opportunities and in-

come to 175 thousand people in South Bra-

zil, starting from52 thousand direct jobs.

Ontheheelsof

success

Inor Ag. Assmann

16